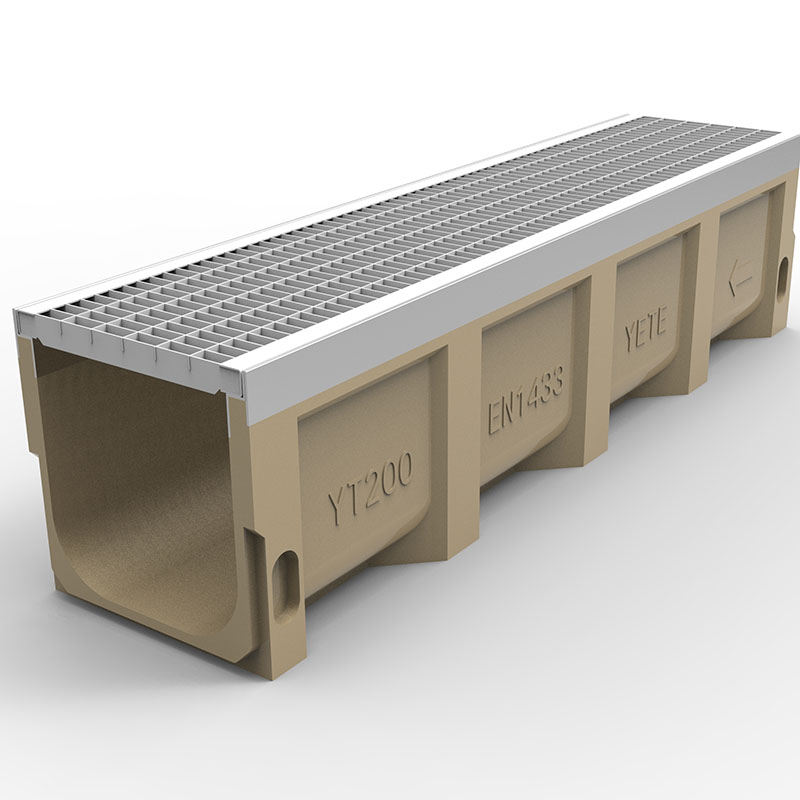

Stainless Steel Drainage Channels With Stainless steel cover plate

Product Features of Stainless Steel Drainage Channels

Introduction

With the rapid development of urbanization, drainage systems play an increasingly important role in a variety of applications. From urban roads to commercial buildings, from industrial parks to high-end landscaping, drainage solutions must not only meet functional requirements but also prioritize durability and aesthetics. Among various drainage products, stainless steel drainage channels stand out for their exceptional performance and versatile design, making them the preferred choice for premium and industrial projects. This article provides an in-depth analysis of the key features of stainless steel drainage channels, helping you better understand their advantages and applications.

1. Core Features of Stainless Steel Drainage Channels

Thanks to the unique properties of stainless steel, these drainage channels offer the following core features:

1. High Strength and Durability

Stainless steel has excellent tensile strength and impact resistance, allowing drainage channels to withstand various loads and external impacts, even in heavy-duty applications.

- Abrasion Resistance: Stainless steel drainage channels maintain their shape and performance even under frequent vehicle traffic, minimizing deformation or damage.

- Corrosion Resistance: Stainless steel is highly resistant to water, oxygen in the air, and chemicals, making it ideal for damp or corrosive environments.

2. Superior Corrosion Resistance

One of the most notable features of stainless steel drainage channels is their excellent resistance to corrosion, especially when made from 304 or 316 stainless steel.

- 304 Stainless Steel: Suitable for general environments, offering good resistance to atmospheric and freshwater corrosion.

- 316 Stainless Steel: Enhanced with molybdenum, providing superior corrosion resistance in marine environments or areas with strong acids and alkalis.

This makes stainless steel drainage channels ideal for chemical plants, food processing facilities, swimming pools, and more.

3. Efficient Drainage Performance

Stainless steel drainage channels are designed with fluid dynamics in mind to ensure quick and efficient water discharge.

- Smooth Interior Surface: Minimizes water flow resistance, enhancing drainage efficiency.

- Precision Slot Design: Accurately calculated openings allow for rapid surface water collection, preventing pooling.

- Versatile Cross-Sections: U-shaped, V-shaped, and rectangular profiles cater to various drainage requirements.

4. Aesthetic Appeal and Compatibility

Stainless steel drainage channels are not only functional but also contribute to the overall aesthetics of a space.

- Modern Appearance: The metallic finish and sleek design make them suitable for high-end commercial areas, hotels, and landscaped roads.

- Customizable Designs: Covers can be customized with different patterns (e.g., slotted or grated) to meet specific aesthetic requirements.

- Strong Compatibility: Stainless steel channels integrate seamlessly with other materials such as stone, concrete, or tiles, creating a harmonious look.

5. Environmental Friendliness

Stainless steel is a recyclable material, aligning with modern principles of sustainable construction.

- Recyclability: At the end of its service life, stainless steel can be recycled, reducing resource waste.

- Safety: Stainless steel is non-toxic and does not pollute the environment, making it ideal for food processing, medical, and other hygiene-sensitive applications.

2. Common Applications of Stainless Steel Drainage Channels

1. Commercial Buildings

Shopping malls, hotels, and office buildings use stainless steel drainage channels to combine efficient drainage with a modern aesthetic.

2. Industrial Facilities

Stainless steel drainage channels are widely used in chemical plants, food processing factories, and pharmaceutical facilities to resist corrosive liquids and high temperatures.

3. Public Infrastructure

Urban plazas, parks, train stations, and airports benefit from stainless steel drainage channels’ ability to handle high foot traffic and heavy vehicle loads.

4. High-End Residential Areas

In luxury homes or villa developments, stainless steel drainage channels enhance the overall quality and functionality of outdoor spaces.

3. Key Considerations for Choosing Stainless Steel Drainage Channels

1. Material Selection

Choose the appropriate stainless steel grade for the environment:

- 304 Stainless Steel: Suitable for general outdoor applications.

- 316 Stainless Steel: Ideal for corrosive environments such as coastal or industrial areas.

2. Load Capacity

Select the appropriate load class (e.g., EN 1433 standard) based on the application to ensure durability under heavy use.

3. Design and Dimensions

Choose the appropriate cross-section and dimensions to meet the drainage requirements of the site.

4. Aesthetics and Customization

Opt for cover designs (e.g., narrow slot, grating) that match the style of the space, and consider custom sizes or finishes if needed.

4. Maintenance and Care

Although stainless steel drainage channels are highly resistant to corrosion, regular maintenance can extend their lifespan:

- Debris Removal: Periodically clean leaves, sand, and other debris from the channel to prevent blockages.

- Cover Inspection: Ensure covers are securely fastened to avoid safety hazards.

- Surface Cleaning: Use mild detergents to clean the surface and maintain its aesthetic appeal.

- Corrosion Checks: In industrial environments, inspect for signs of corrosion and treat if necessary.

5. Conclusion

Stainless steel drainage channels are a vital component of modern drainage systems, offering exceptional strength, corrosion resistance, efficient drainage, and aesthetic versatility. Whether used in commercial spaces or industrial environments, they meet the demands of complex applications while enhancing the overall quality of the infrastructure. By selecting the right material, design, and dimensions, and ensuring proper maintenance, stainless steel drainage channels provide long-lasting and reliable performance for a wide range of projects.